qSPRINT

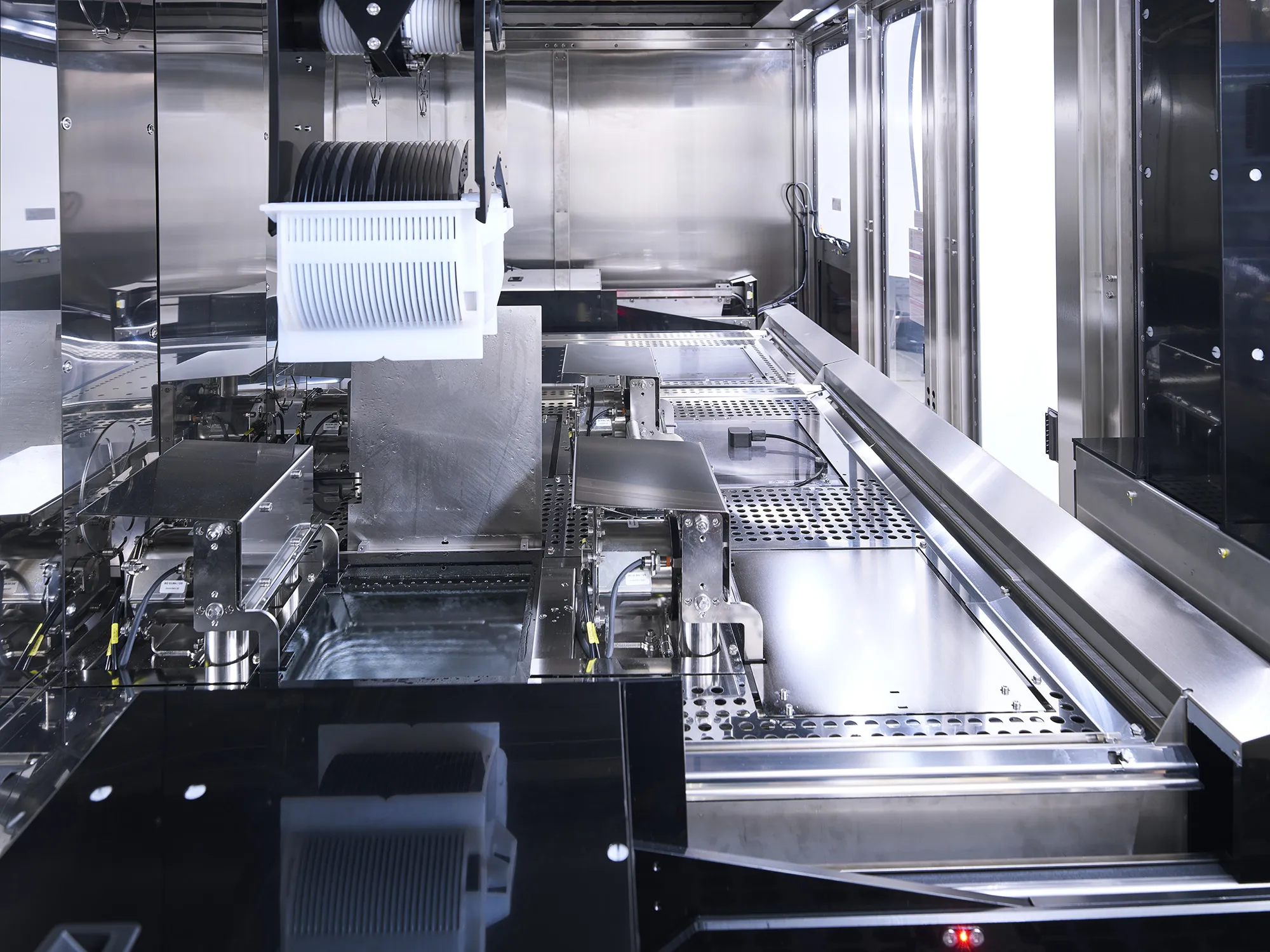

qSPRINT is a compact automatic wet process system for versatile use in a wide variety of industrial sectors – from general manufacturing to the semiconductor industry. It was newly developed to cover a maximum range of wet chemical processes such as cleaning, etching, rinsing and drying in minimal space (smallest footprint). Its robust design and precise process control ensure the highest stability and reproducibility even under cleanroom conditions. Thanks to its universal applicability, the qSPRINT is in demand worldwide in development and production environments alike.

The system software enables flexible recipe management, which allows individual process sequences and parameter adjustments. This allows the system to be optimally adapted to different applications and offers maximum process diversity with simultaneously efficient operation and high productivity.

Convincing Software

- Individual recipe management

- Multi product management

- Configurable trend evaluation

- User management

- Alarm management

- SECS/GEM and OPC UA ready

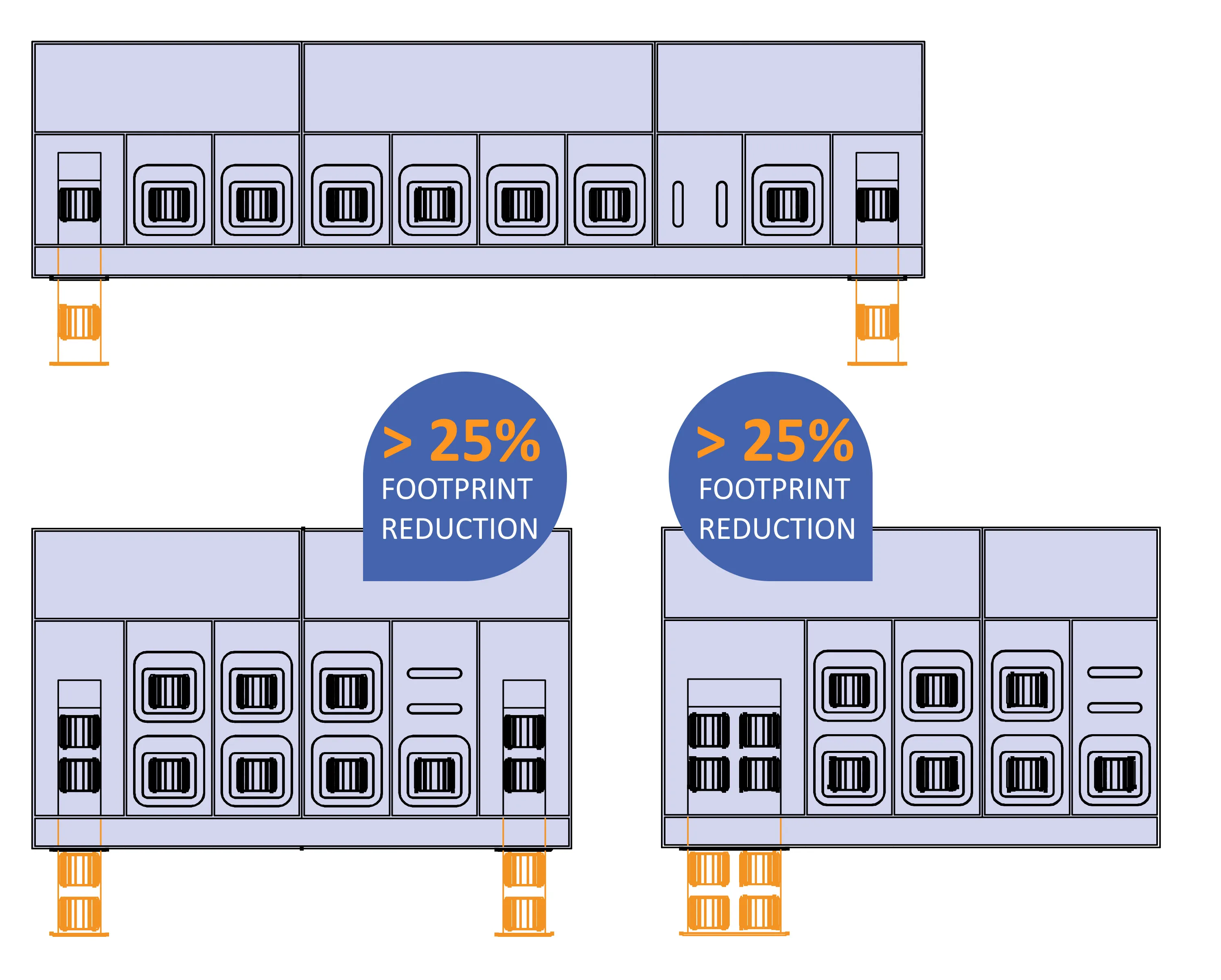

Maximum configurable

- One or two bath raws

- Carrier buffer in Load/ Unload station

- Individual baths

- Ultrasonic/ Megasonic

- Wafer agitation

- Wafer rotation

Easy FAB integration

- Footprint very low

- control cabinet incorporated

- Chiller and heater system incorporated

- airflow actively controlled

- Fast installation

Commercial advantages

- Short delivery time

- Strong price performance

- High availability

- Transparent spare parts pricing