qCAR

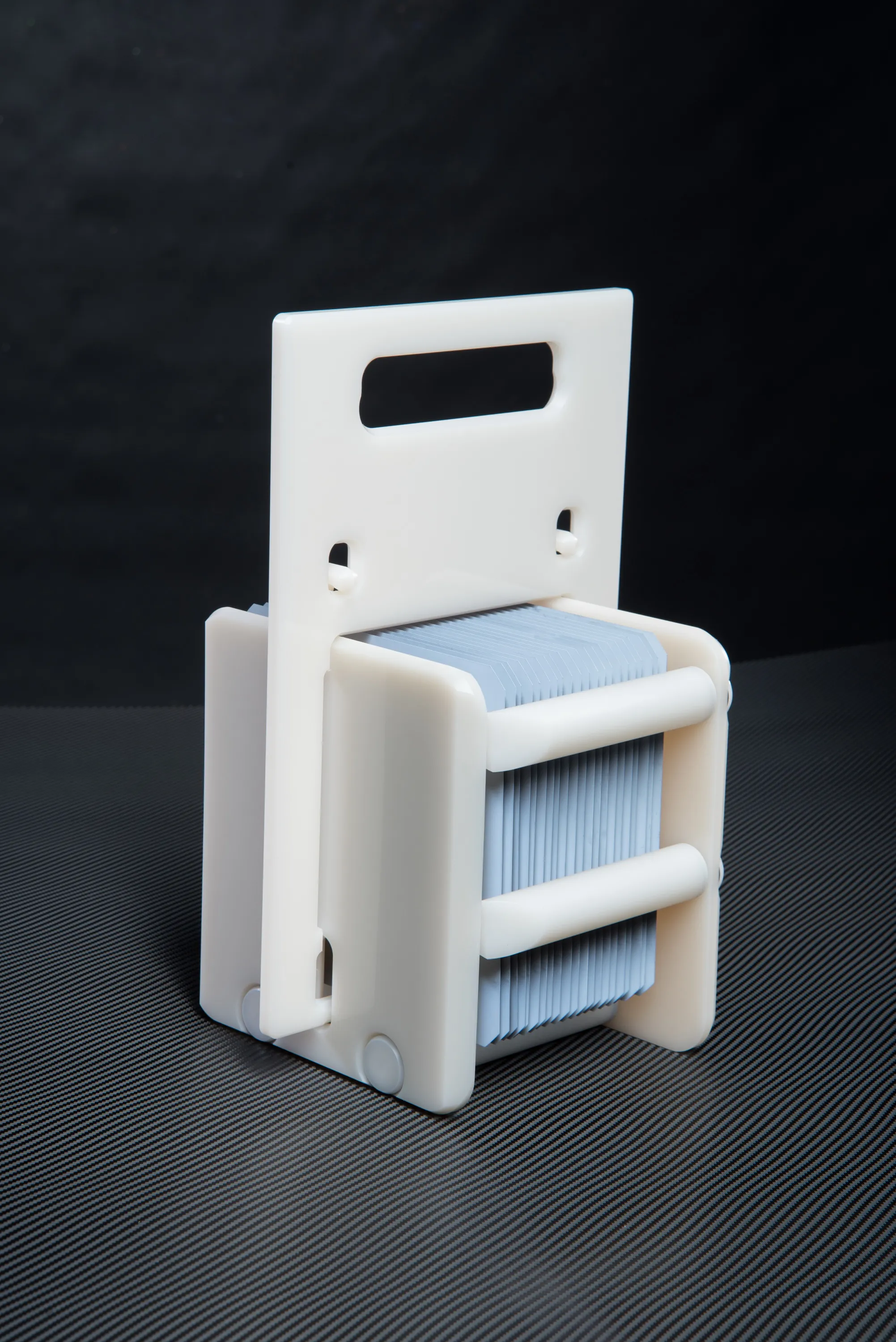

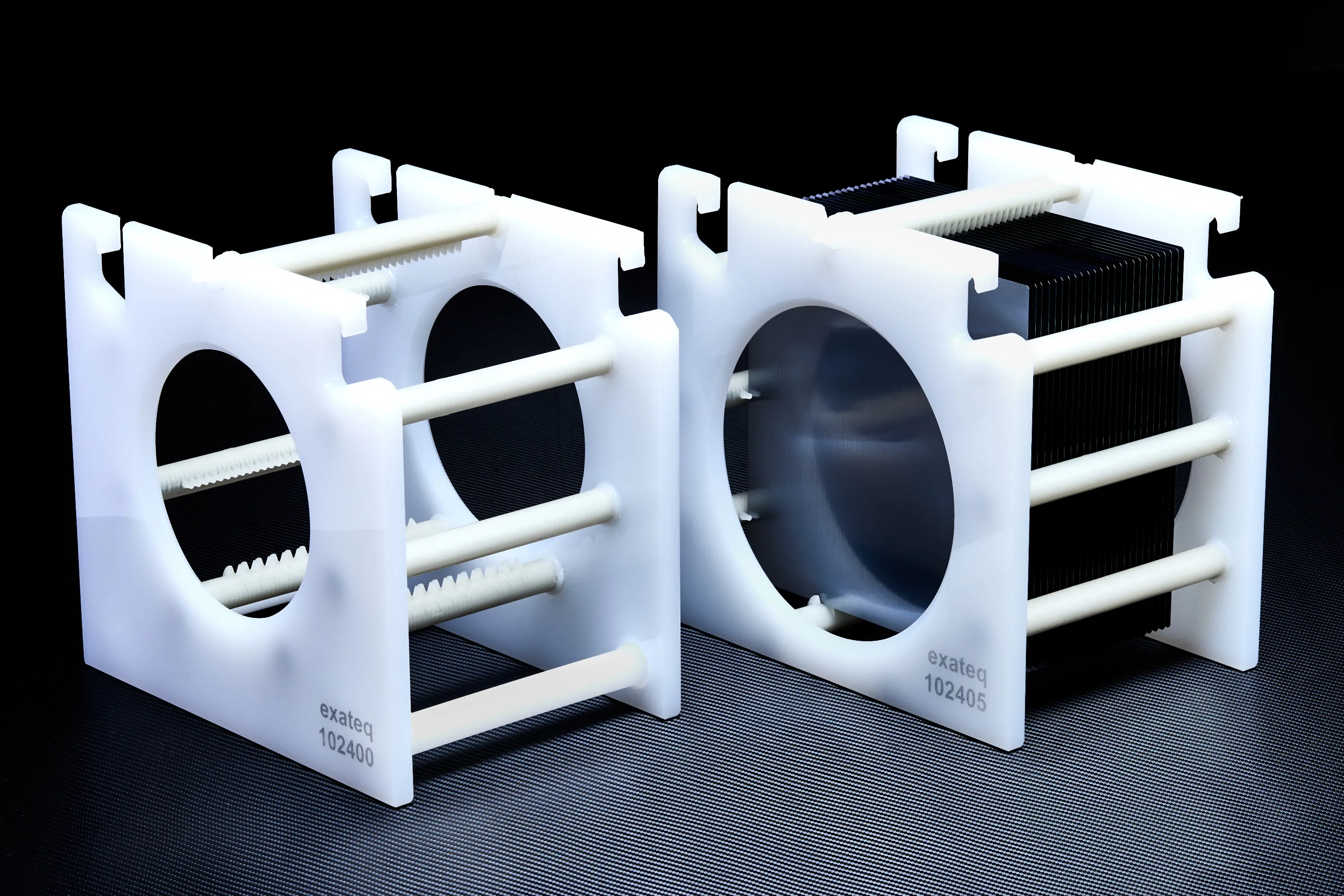

With the qCAR we offer precise and durable carrier solutions for reliable process and material transport in wet process systems. Manufacturing is carried out completely in-house – from injection molding production through welding and annealing processes to final quality control. This enables both series and individual productions to be realized efficiently and reproducibly.

Depending on the application area, chemical-resistant materials are used that ensure the highest stability and durability. The specially developed tooth geometry is optimized for secure holding properties, maximum automation capability and efficient drying of the substrates.

In addition to our standard systems, we also manufacture individual carriers that are precisely tailored to customer-specific requirements, substrate geometries and process conditions. With our many years of experience and several thousand manufactured carriers, qCAR stands for mature quality, process reliability and compatibility with a wide variety of system concepts.

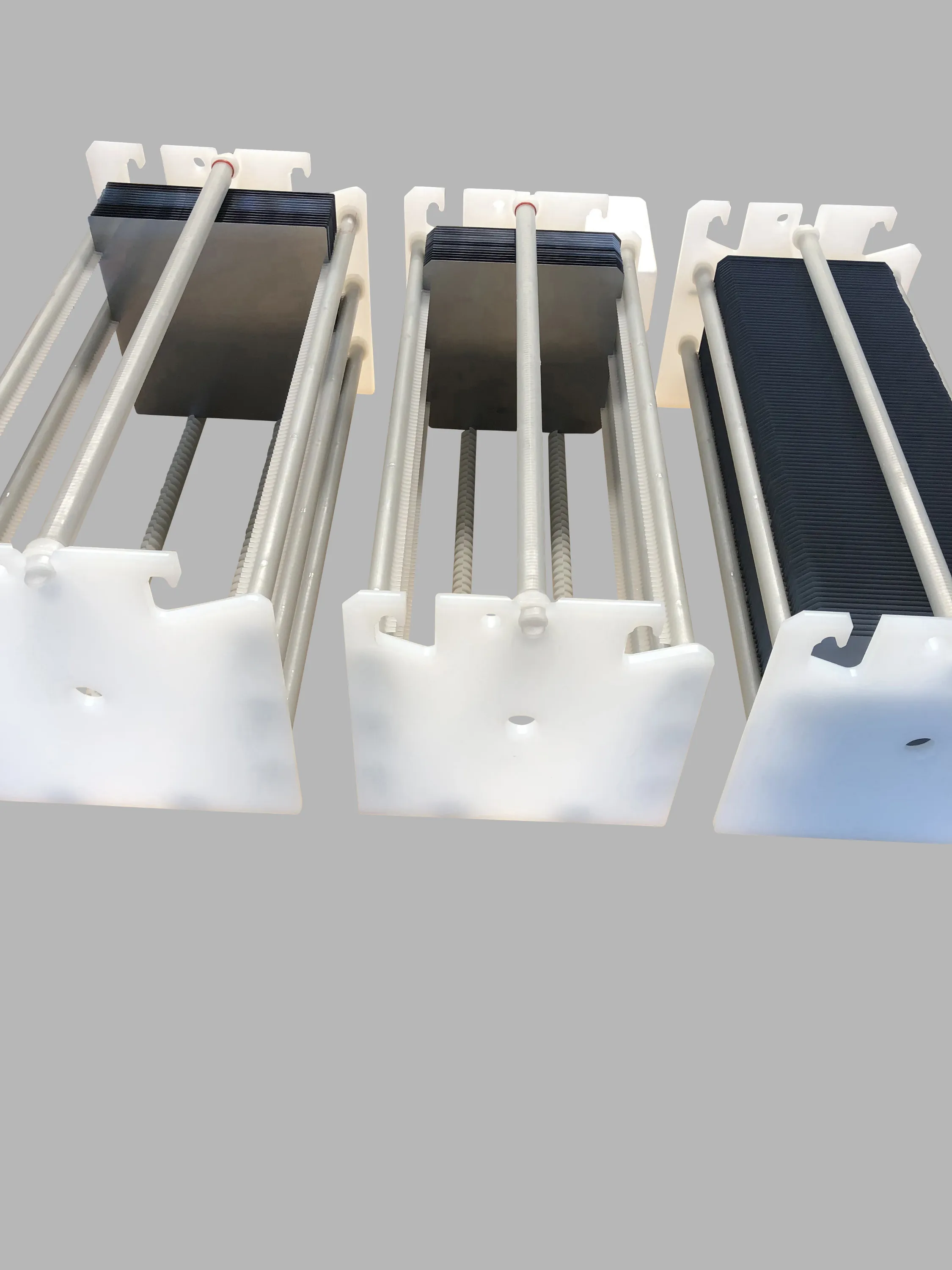

Scalable wafer numbers and wafer size

- Single wafer

- PV wafer

- Semi-wafer

- Substrates (up to 600x600mm)

Tailored to process requirements

- Drip edges

- Drying optimized slot geometries

- Temperature resistant

- Hold-down systems

- Automatable

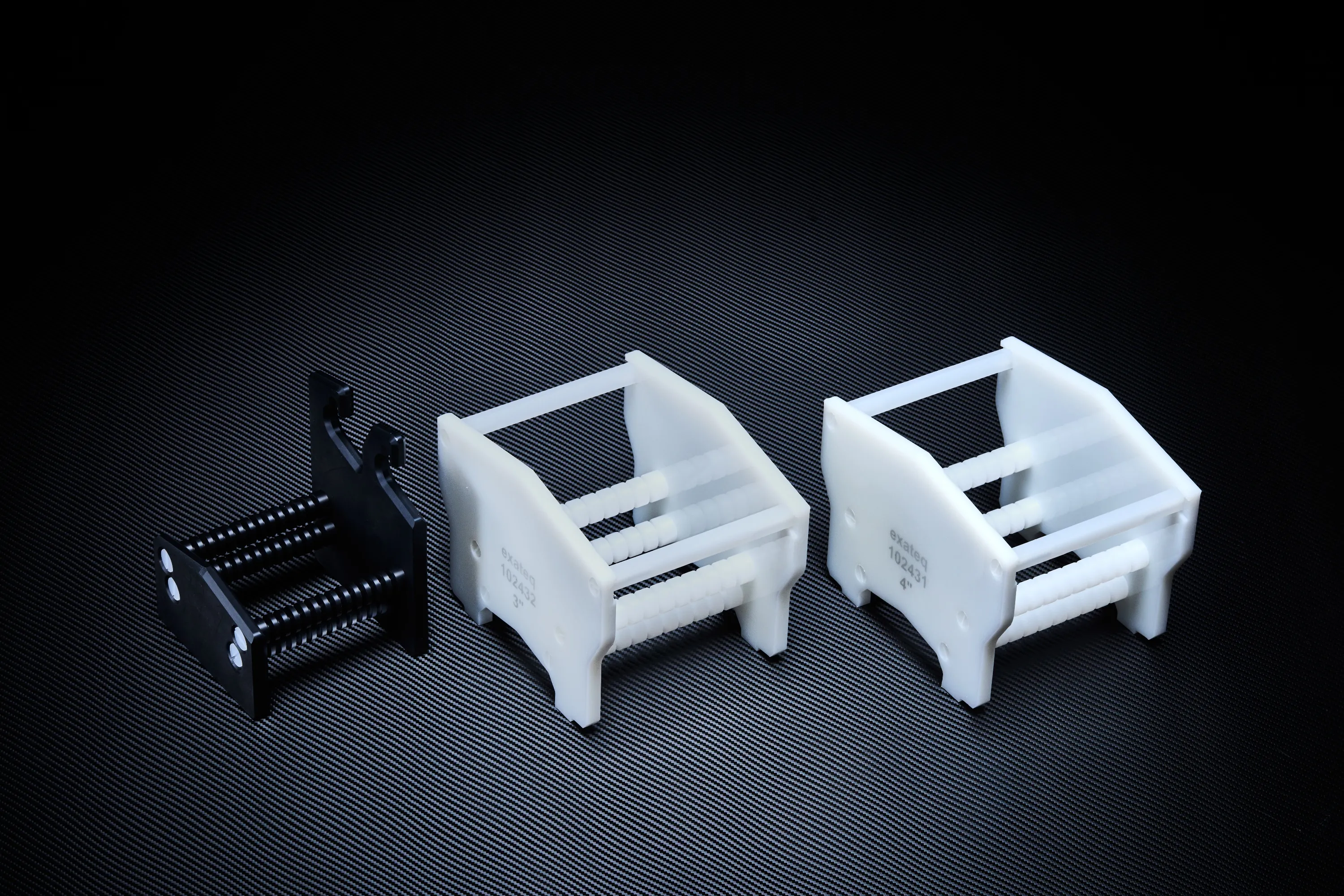

Versatile manufacturing possibilities

- Injection molding

- Manual welding

- Machine welding

- Annealing

Various materials

- PVDF

- PFA

- PP

- Stainless steel

- Conductive plastics